Protan PVC roof membranes are successfully used on renovated, flat and pitched roofs. The company offers reliable, easy-to-mount and fully equipped waterproofing solutions for planes and junctions. The systems operate on exploited and unexploited housetops. Emimar offers four groups of roofing systems for various applications:

- mechanically fixed;

- vacuum;

- ballast and inversion;

- adhered.

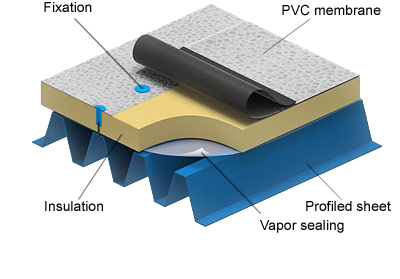

1. Mechanically fixed roofing systems

This is the most cost-saving and quick method. Ideal for pre-fabricated industrial, warehouse, cultural, entertainment, shopping and sports facilities. Fastening methods: self-tapping screws with plastic housing (for profiled sheets) and concrete screws (for concrete surfaces). In addition, clamped-on installation is used when creating balconies and terraces where Protan products are used as topcoat. There are 2 types of mechanically fixed (clamped-on) roofing systems:

- standard overlap;

- secret fix strip system (SFS).

Mechanically fixed roofing systems: standard overlap system

Protan SE membrane (up to 2 m wide) is fixed to the substrate within its sidelap and overlapped by the adjacent sheet.

Standard width options: 0.67 m -1 m -1.33 m and 2 m (1 m and 2 m options are most common).

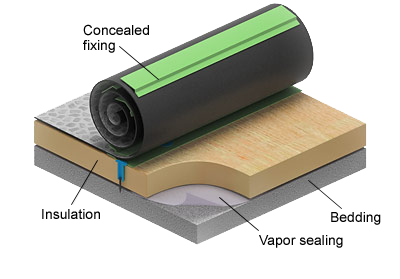

Mechanically fixed roofing systems: secret fix strip system

The system provides great resistance to wind uplift because fixings are distributed over the entire membrane area. Ideal for installation in windy conditions. Requires much less fixing and welding.

The system provides great resistance to wind uplift because fixings are distributed over the entire membrane area. Ideal for installation in windy conditions. Requires much less fixing and welding.The system has been developed with high strength backing strips which are factory welded to the underside of the membrane at a distance of 80-120 cm from each other. Secret-Fix System may be specified on projects where uplift is a significant factor.

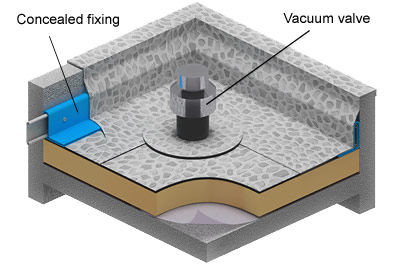

2. Vacuum Roofing System

Strategically placed vents create negative pressure within the system fixing the membrane to the substrate. Membranes are mechanically fixed only around the perimeters and penetrations. This method is recommended for the reconstruction of old bitumen roofs as it is cost effective and does not pose any technical restraints for using ballast or mechanical fasteners. No fasteners ensure rapid installation with reduced labor time.

Vacuum roofing is used in circumstances when mechanical fixing is not desirable:

Vacuum roofing is used in circumstances when mechanical fixing is not desirable:

- damage (delamination) of ceiling constructions;

- inadmissibility of vapor barrier perforation;

- deck is unsuitable for mechanical fixing;

- great insulation thickness;

- potential thermal bridges at a small thickness of thermal insulation.

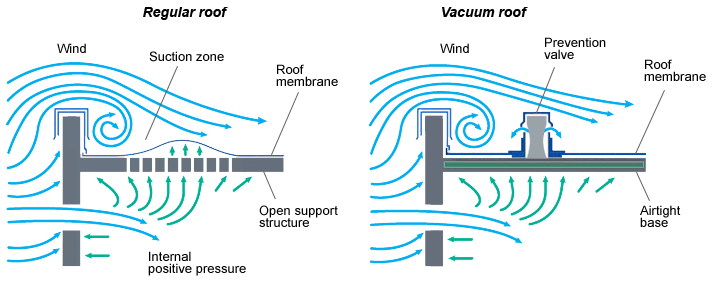

Principle of vacuum roofing

When the airflow causes negative pressure to form over the roof, the air volume between the roofing membrane and the airtight underlay expands, and it expands most where the negative pressure is greatest, i.e. in corner and edge zones. In order to «drain» out this positive pressure and any losses from leaks, so-called vacuum vents are installed where the negative pressure is expected to be greatest.

Vacuum-roofing systems can be used both for new roofing and for reroofing. The system requires an airtight layer or barrier in the substrate. This makes it particularly well suited for reroofing projects where the existing roofing membrane is still considered to be sufficiently intact and with sufficient anchoring to the supporting system. Old bitumen membranes, with open blisters and overlaps and with questionable adhesion to the underlay, are an example of an unsuitable underlay. Protan vacuum systems have been used to cover more than 2,000,000 m2 of roofs.

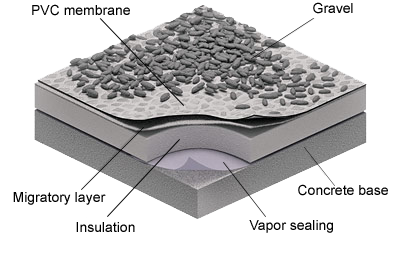

3. Ballast and inversion roofing systems

Covered membranes in roof structures are generally referred to as ballasted roofs. The ballast material may be concrete slabs, shingle, or soil as the surface for a planted roof. Inverted roofs are variations of ballasted roof constructions where insulation is used over the membrane in order to provide extra protection.

Ballasted roof systems offer a number of advantages for wet room waterproofing, organizing pedestrian areas and car parks.

Ballast and inversion roofing systems: gravel ballasted roofs

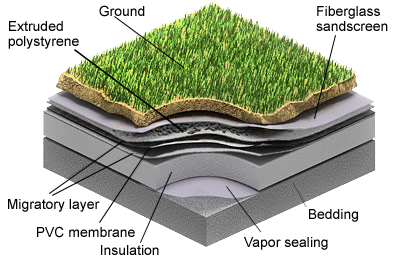

Ballast and inversion roofing systems: green roofs

Apart from obvious environmental advantages, green roofs require minimal maintenance, provide a good sound and heat insulation, remove water and extend the life of the membranes.

Apart from obvious environmental advantages, green roofs require minimal maintenance, provide a good sound and heat insulation, remove water and extend the life of the membranes.Besides, they look great.

Thanks to Protan membranes, designing a green roof becomes an attainable goal.

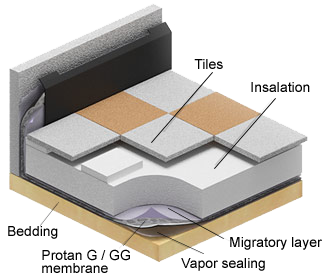

Ballast and inversion roofing systems: wet areas, car parks and recreational areas

Installing Protan waterproofing membrane under cast concrete is the classical solution for wet rooms.

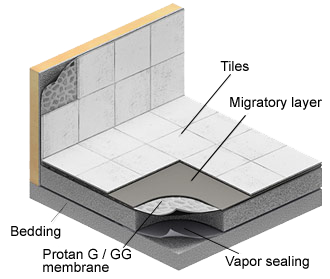

4. Adhered roof systems

The Protan Adhered System is fully bonded to the substrate or insulation. This makes it ideal for buildings with concrete decks where mechanical attachment is difficult.

The Protan Adhered System is fully bonded to the substrate or insulation. This makes it ideal for buildings with concrete decks where mechanical attachment is difficult.Adhered roof systems use Protan EX-A 1,6mm fiberglass reinforced membranes glued to contact adhesive and polyurethane adhesive.

Protan adhered roof systems are used where mechanical fixing cannot be applied.